Product List / Alumina

Alumina / Al2O3

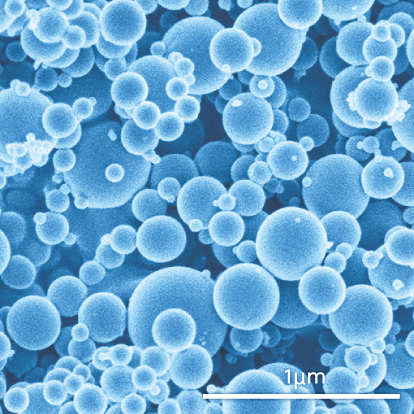

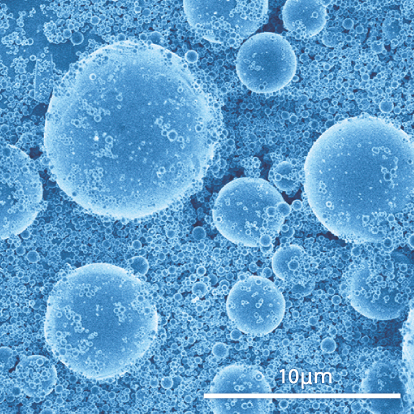

High-purity synthesis spherical alumina

- ● Two average particle sizes are available: 0.25 µm and 10 µm.

- ● High purity, high sphericity, non-porous surface, and excellent dispersibility.

- ● Different to molten alumina, this alumina contains fewer ionic impurities such as Na,

so it can also be used for high-heat resistant or high-voltage resistant applications. - ● Alumina with higher purity than the AO-5 type can also be provided.

- Particle diameter

line-up /

Purity

(impurity) data - Paticle size distributions /

SEM images - Products

& App

Application

- ● Filler for thermal conductive compounds

- ● Ceramics molding products

- ● Filler for light scattering agent

Display

MORE

● Particle diameter line-up

AO-5 type regular grade

| Product name | Median particle diameter (μm) | Specific surface area (m2/g) |

|---|---|---|

| AO-502 | 0.2~0.3 | 6.5~9.0 |

| AO-509 | 7~13 | 1.0~1.8 |

● Purity (impurity) data

| AO-5 type regular grade |

||

|---|---|---|

| Composition | Al2O3(%) | > 99.8 |

| Moisture content(%) | < 0.3 | |

| Fe(ppm) | < 1500 | |

| Si(ppm) | < 1000 | |

| U(ppb) | - | |

| Ionic impurities |

Na+(ppm) | < 1.0 |

| K+(ppm) | < 1.0 | |

| Cl-(ppm) | < 2.0 | |

| Extraction properties |

EC(μS/cm) | < 5 |

| pH | 4.5~6.0 |

AO-502

AO-509

- ※ ADMANANO is a registered trademark of Admatechs Co., Ltd.

- ※ The figures presented on this page represent typical values only, not guaranteed values.

- ※ The particle sizes presented in this material are values that we obtained by using a laser diffraction particle size analyzer.

For this reason, the products presented herein contain a very small amount of very fine and coarse particles.